Multiwell microplates come in a wide range of sizes, volumes, shapes and treatments, but very often the perfect plate, that meet every customer need does not exist. This may be a simple requirement for packaging plates in a different quantity or using a different treatment, but what happens when the customer application demands a different shape or plate structure that just does not currently exist on the market.

Continuous innovation of new scientific techniques, instrumentation or applications can require particular plate design alterations that are unique to each customer. Eg, shorter or flatter plates, more angled, a different shape, volume, or thicker bottoms. If the plate that meet all the essential requirements is not available, the application can be compromised. The answer could be a custom made plate with the perfect design to meet the needs of the application.

Porvair Sciences has been designing mould tools for scientific multiwell plates for over 40 years. This includes our own product range as well as bespoke plates specifically for our individual customers. We specialise in understanding innovative requirements, and putting them into reality.

Through the years, we have implemented a simple process to ensure concept to perfect plate development:

Over the past few years, to fit in with new automated workflows, new instrument designs with unique capability and specific high through put demands, Porvair Sciences have created many unique plates with customised characteristics: shorter or flatter plates, more angled, a different shape, volume, or thicker bottoms at the request of our customers. From their initial enquiry to tool design, approval and finally full production and treatment service, these customers now have a custom plate that meet all the requirements to get the best application results.

If your new technique or application needs a plate that isn’t currently available, rather than compromising your results, contact us at int.sales@porvairsciences.com to discuss a bespoke plate options that would work for you.

Porvair Sciences has launched a range of Ultraseal™ heat-sealing films that display key film characteristics on each sheet. The information clearly identifies; which plates the heat-sealing films can be used with, how thick the seal is and whether they are peelable and/or pierceable. The new Ultraseal™ range also includes clear films suitable for qPCR, wider temperature ranges and solvent compatibilities.

As, sealing multiwell plates is an essential step in many application workflows to control sample changes over time, protecting samples from the atmosphere or from changing concentration as solvent evaporates, the seals are used as a form of a physical barrier.

Due to numerous sample and application characteristics however there are many performance requirements for the seals on a variety of different plate types, E.g. a sample may need to be injected into an analysers so the seal needs to be pierceable, the seal also may need to be removed to allow another reagent to be added which would require it to have peelable characteristics. Laboratories also often use different plates, such as polypropylene for storage and collection or polystyrene for assay an incubation. Depending on the construction of the seal, it may have a very specific features that would allow it to seal only certain plate types.

Most seals on the market are either clear or have an aluminium layer, that makes it difficult to differentiate between them. This does not create an issue if the laboratory is using one seal type for a single application method while using the same plates, but if there are different applications on the same heat sealer or the laboratory’s work is project based with different requirements weekly or even daily, the inability to distinguish between the seals can cause a confusion. The new Porvair Sciences Ultraseal™ range of heat seals have been designed with a clear indications and relevant film information to avoid the confusion.

With film characteristics clearly printed on every seal, it reduces the risk of using the wrong film, and potentially lowering the wasted time and samples. Each information strip is also colour coordinated, that allows for an easier seal recognition for an extra security.

Our Ultraseal™ range of colour coordinated seals is fully compatible with the Porvair Sciences Ultraseal™ Lite heat sealer. A manual system that controls sealing parameters (temperature and dwell time) through a simple touch screen to provide fast reliable plate sealing.

Reach out to our team to find out more about our colour coded Ultraseal™ heat-sealing films and Sciences Ultraseal™ Lite Heat Sealer.

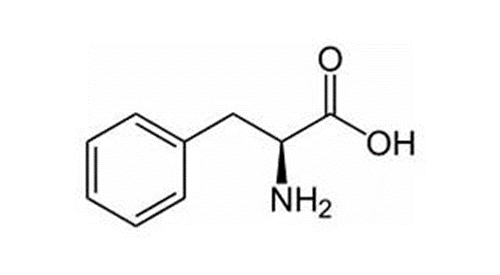

About Phenylketonuria (PKU)

Phenylketonuria (PKU) is a rare but potentially serious inherited metabolic disorder. Here’s what you need to know:

Our Journey

Meet My Fiancée Harriet

My incredible fiancée, Harriet, faces PKU head-on every day. Despite the challenges, she remains resilient, determined, and full of love. An average day for Harriet would start with her having to take 14 tablets before breakfast of a drug known as KUVAN ® (sapropterin dihydrochloride) – This is something that was fairly recently discovered and is used to help sufferers of PKU consume more protein. After the tablets, Harriet is then required to have supplements 3 times a day to help her get all the nutrients she cant get from eating protein. And to put in perspective just how challenging it can be, Harriet is usually only allowed 4g of protein everyday – 1 pack of Ready salted crisps is 1.5g-2.0g of protein. So there is no room for error with measuring meals, through weight and quantity.

Then even with all she already has to do, she is also required every 2 weeks to submit blood tests to the dietitian so they can analyse her levels to check they are not too high. This is circumstantial, if she wanted to try for a baby, this changes to 2-3 times a week, rather than every fortnight.

It is not always easy for her to manage and we get lots of help from our families, however some people are not so lucky and either don’t get enough support or find out too late and irreversible damage has already been done.

Why We’re Raising Funds

We’re on a mission to raise awareness about PKU and support others facing similar battles. The National Society for Phenylketonuria (NSPKU) has been a lifeline for us. NSPKU, founded in 1973, is the national charity for people living with PKU in the UK. They provide vital information, advocacy, and community support.

How You Can Help

By donating to our JustGiving page, you’re contributing to:

Join Us!

Let’s stand together and make a difference. Your contribution matters more than you know. Click here to visit our JustGiving page and be part of our journey.

Thank you for your kindness and support!

Porvair Sciences introduce the new UltraPPM LITE positive pressure system for sample preparation. A simple, reliable and reproducible instrument for increasing throughput of multiwell processing plates.

The Porvair UltraPPM features an interchangeable head design that allows for a simple user switch between 96, 48, 24 and 384 well filter plates. This makes it the most versatile pressure manifold available and ideal for laboratories with changing projects.

Many sample preparation process’ require solvent to pass through a filter held within a multiwell plate. The filter itself might be a simple particulate filter, or a more complex chemically active system to extract target analytes from a sample. In any application the filter acts to resist the flow of the sample and solvents, which can lead to delays and long processing times. For many years Porvair Sciences has manufactured a vacuum manifold the increases the pressure difference across this filter thereby decreasing the time needed to process a plate. The alternative is to apply a positive pressure to the head of the plate forcing the solvent through rather than pulling it.

Positive pressure has a number of advantages over vacuum. Vacuum may not be strong enough when analysing viscous samples, the gas source used can be controlled unlike using lab atmosphere, it is easier to operate since there is no vacuum release required, which needs to be carried out in a controlled slow way to prevent disturbing the collected eluants and potentially cross contamination.

For further information, please visit https://www.microplates.com/product/ultrappm-lite-positive-pressure-manifold/

Many applications in analytical and life science laboratories need to ensure samples are kept in a protected environment while they are processed, stored or incubated. This might mean preventing solvent evaporation, absorption of moisture or contaminants from the atmosphere, or being affected by oxygen.

When high throughput labs use multiwell plates, sealing is most commonly performed with a heat or adhesive seal. Adhesive seals can be applied manually using a roller or soft scraper, but heat seals need some form of applicator. There are many different types of heat seal available (many from Porvair Sciences) that offer different behaviours to meet the needs of the application. Permanent or peelable, robust or pierceable, clear, optically clear for qPCR or even breathable, but they all need a method of evenly applying heat across the film to ensure a robust and uniform seal.

Choosing the right instrument used for a lab depends on a number of criteria, the main ones being the availability of compressed air, the number and frequency of plates to be sealed and whether they are to be integrated into a laboratory robotics system.

Porvair Sciences are experts in plate sealing and can match your requirements to an instrument. From a semi-automated system with settable time and temperature that uses individual film sheets, to a fully automatable system that uses a roll of film. All the systems can accommodate thin assay and PCR plates, to deep well storage plates without the use of adaptors or changing carriers.

If your application demands samples are sealed in a specific atmosphere, purge options are available. If you need to automate, but do not need the capacity of a roll to seal 5000 plates, the unique frame sealer UltrasealTM ePRO-MINI. If high through put is needed, the UltrasealTM PRO can seal up to 6 plates per minute.

If you prefer adhesive seals, but still require automation, the UltrasealTM COLD-PRO is an automatable roll fed instrument that can separate the adhesive film from its backing and apply it to up to 3 plates a minute.

Our range of sealers provide a wide range of capability and functionality to meet the needs of any lab needing to protect its samples.