SKU: 500292

Blowdown Evaporator for tubes up to 150mm high, Mistral XT150 (110/230V)

(Needle head not included)

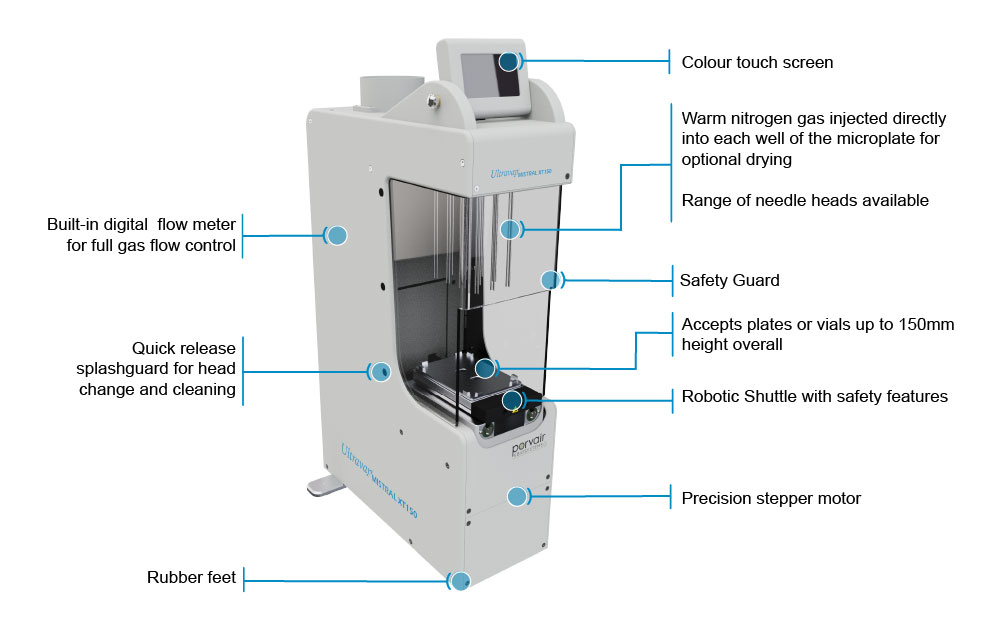

Porvair Sciences Ultravap® Mistral blowdown evaporator is designed to remove the traditional laboratory bottleneck of solvent evaporation from glass tubes. The new flat front profile and platform shuttle enables greater interfacing with liquid-handling robots for increased automation efficiency. Reproducible sample throughput is achieved by advancements in gas injection technology to directly and consistently deliver heated gas in each tube (up to 150 mm in height).

The Ultravap® Mistral XT150 is the most sophisticated automation-friendly model yet, giving significant throughput advantages to laboratories looking to optimise microplate sample preparation. The Ultravap® Mistral XT150 has been designed in close cooperation with the leading suppliers of laboratory liquid handling robots. The result is a fully robot compatible evaporator, suitable for integration directly with the following leading laboratory liquid handling robots:

l Hamilton Robotics l Tecan l Perkin Elmer l Beckman Coulter l Agilent

Designed with the demands of linear robots very much in mind, the Ultravap® Mistral XT150 offers a plate shuttle which can serve and retrieve plates from the deck of most liquid handlers. The colour touchscreen controlled dry down station accepts interchangeable 24, 48, 96 or 384 needle heads. Clear safety screens and integral fume management leading to a 4-inch duct adaptor that incorporates a fan for high speed fume removal ensure safe operation.

Flexible Programming

The Ultravap® Mistral XT150 has the capability to program and store 15 different methods. Allowing the user defined setups for different solvents or volumes. The methods can be programmed to precisely move the sample carrier up and down at an appropriate rate, in 0.1 mm increments, ensuring the needles effectively direct gas onto the solvent as it evaporates. This movement can be programmed with 5 distinct gradients. This allows for faster initial drying at the start, followed by slower gradients towards the end. Additionally, the gas temperature and flow rate can be programmed into the methods to allow for further flexibility.

Smart Safety

The Ultravap® Mistral XT150 has been designed to protect you and your robot from harm, while looking after your samples. The moving plate shuttle has sensitive micro switches to detect obstacles or obstructions both on and off the robot deck. If triggered, this safety system automatically stops the Mistral and prompts the user to clear the obstruction before re-setting the plate shuttle.

Efficiency in the Production Environment

The Ultravap® Mistral XT150 software has been specially designed and developed to control multiple Mistral “slave” units from a single “master” evaporator. Using the latest CAN interface technology, any number of Mistral XT150 units can be connected in series. When a method is selected on a master unit, it is automatically distributed over the CAN bus to all the slave units which subsequently run the programme simultaneously.

In addition, a master unit can be operated directly over the built-in RS232 link, allowing for remote programming and start/stop commands to be sent over a network. All slaved units will respond to these commands, allowing the instrument to be highly effective in a production environment. Station I.D. numbers can be set and stored for each master and slave unit. Units can be easily switched out of ‘Remote Control’ mode, without disconnecting the CAN bus, for maintenance or where a random-access programme is required.

Method Security

The ability to modify stored methods is controlled by a password-protected Administrative User level in the Mistral software. This ensures that unauthorised users are unable to make changes to stored protocols. Non-administrative users can only view and run stored methods approved by the Administrator.

| Instrument Type | Evaporator |

|---|---|

| Qty/Pack | 1 |