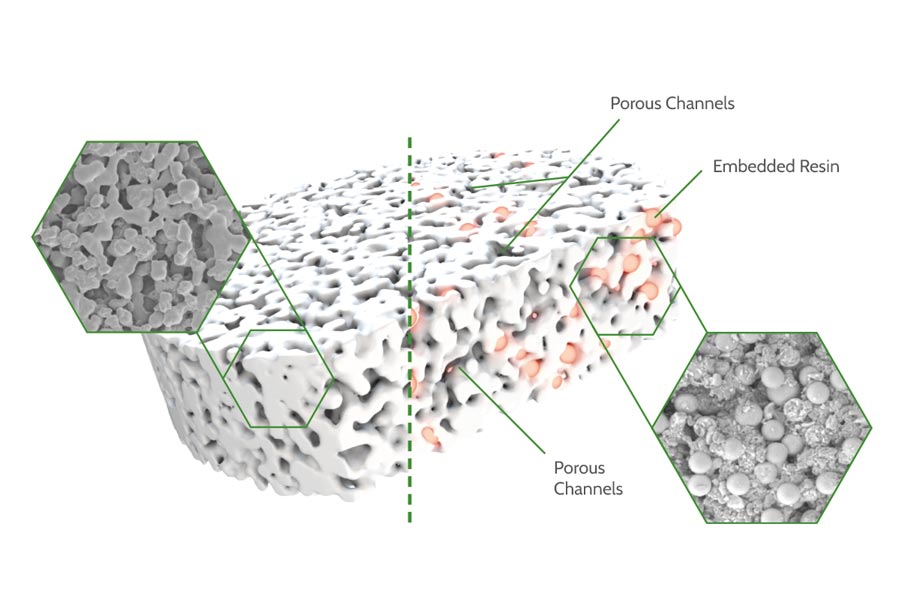

Our unique Microlute® product range features a novel composite technology that combines chromatographically active resins with inert polyethylene. The porous and robust filtration frits formed by this process have been specifically designed to improve consistency and reproducibility of sample preparation for chromatography.

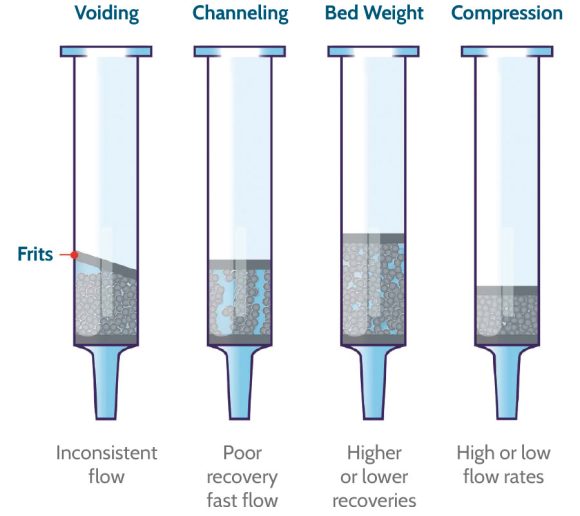

The traditional loose packed format of sample preparation products consists of resin sandwiched between two polyethylene frits. These products, while functional, can be susceptible to variability due to the packing process. Inherent issues such as voiding, channeling, variable bed weights and compression can lead to highly variable flow rates and unreliable analytical data.

Immobilising resin in the Microlute® composites eliminates the limitations of loose packing ensuring the best attainable data.

Key Features:

Flow consistency:

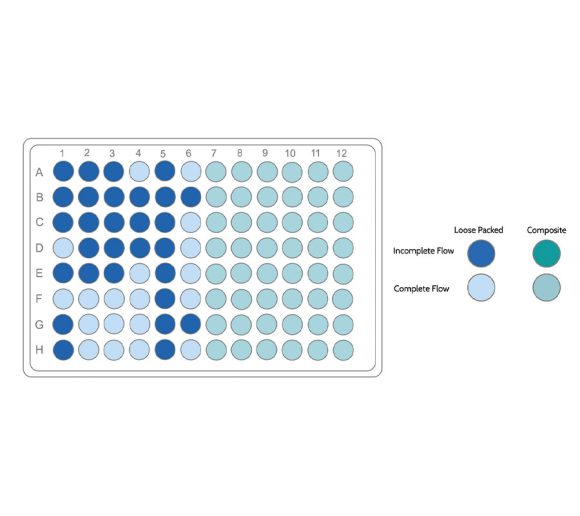

When comparing liquid flow between a loose packed plate and Microlute® composite plate, the composite plate outperforms the loose packed plate with its wells emptying uniformly.

To view a video of the flow advantages of the Microlute® range, click here

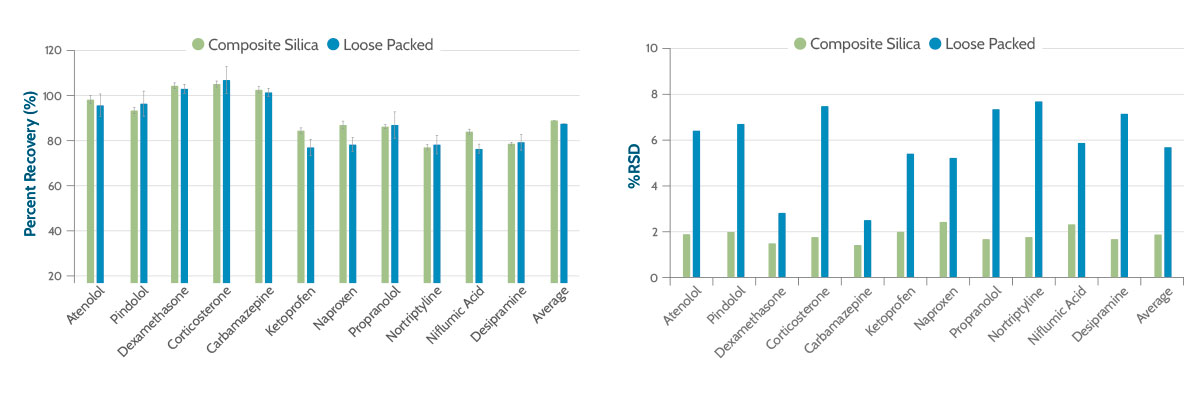

Reproducible analyte recovery across multiple compounds:

In a comparative study between loose packed and composite products, using the same bed weight and resin batches, the composite plate showed greater reproducibility without any reduction in recovery.

To find out more about the reproducibility benefits of the Microlute® composite range, click here

More coming soon

For any more information please contact us here

See below our Microlute® products: